- Home

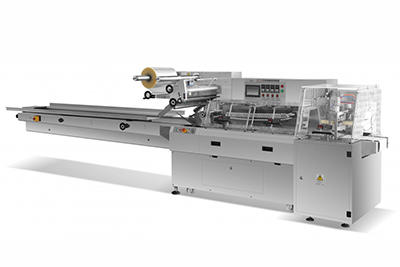

- Horizontal Flow Wrappers/Flow Pack

The horizontal flow wrappers performs the flexible packaging of multiple product types. The choice of pack composite film is plentiful. The wrapping machine and food production line are integrated, forming a complete automatic packaging production line.

-

-

- DXD-280View

Our DXD-280 flow wrappers are designed for the high efficiency packaging of solid products such as hamburgers, instant noodles, bread, mechanical parts, and more.

The DXD-280 flow wrapper is the shrink version of the DXD-580. The maximum film width is 300mm. It is an economic multi-functional HFFS wrapping machine.

Adopting the low film packing method, the DXD-280 flow wrapper is suitable for the packaging of piece parts, goods with water and other irregular products. The production capacity is 50-190 bags/min. The bag length is 150-450mm, and the width is 25-110mm.

-

-

-

- DXD-300View

The DXD-580 Horizontal Wrapper Equipment is specially designed for solid products such as hamburgers, instant noodles, bread, and more.

DXD-580(DXD-580 series flow pack wrapping equipment is a high efficiency and multi-functional horizontal flow pack wrapper. The packing method of low film packing is suitable for the packaging of piece parts, goods with water and irregular products.

-

-

-

- DXD-300/420View

Our DXD-300/400 flow wrappers are packaging machines designed for multiple products such as biscuits, chocolate, ice cream, and more.

The DXD-300 flow wrapper is an economical, multi-functional (HFFS) horizontal flow wrapper carrying out the processes of cutting and packaging. It features the advantages of a compact machine body and low cost.

The DXD-300 adopts an up-film packing method. It can package single or multiple products of various types using a variety of composite film types.

-

-

-

- DXD-580View

The DXD-580 Horizontal Wrapper Equipment is specially designed for solid products such as hamburgers, instant noodles, bread, and more.

DXD-580(DXD-580 series flow pack wrapping equipment is a high efficiency and multi-functional horizontal flow pack wrapper. The packing method of low film packing is suitable for the packaging of piece parts, goods with water and irregular products.

-

-

-

- DXD-630View

DXD-630W horizontal wrapper equipment is a flexible piece of machinery designed for the packaging of products such as hamburgers, instant noodles, household products, medical products, and so on.

We provide two kinds of flow pack wrapping machine, the HFFS pack wrapper and VFFS pack wrapper.

TheDXD-630W horizontal wrapper equipment is a reciprocating type horizontal flow pack wrapping machine (HFFS). In this packaging process, the packaging film is first sealed, and then it is cut after transported traveling a set distance. This kind of pack form guarantees a delicate package appearance, good integrity preservation and freshness of the product.

-

-

-

- DXD-630WView

The DXD-630 series wrapping equipment are designed for the packaging of large products such as hamburgers, instant noodles, household products, medical products, and more.

The DXD-630 series wrapping equipment is a kind of rotating horizontal flow pack wrapping machine, or rather, it is a HFFS wrapper for flow packing lines. The maximum width of the packaging film can reach 450-600mm.

-

-

-

- DXD-800QView

Our DXD-800Q series wrapping equipment is designed for stretch packaging for products such as toffee, instant noodles, bubble gum, nougat, haw jelly, and more.

The DXD-800Q series wrapping equipment is a kind of mufti-functional horizontal flow wrapper with the function of food cutting and packaging.

Equipped with a rotating cutting head, the DXD-800Q has the advantages of fast cutting speed and high packaging efficiency.

In addition, multiple optional configuration modules can be selected by customers according to the special requirements to improve the productivity and service life of the machine.

-

-

-

- DXD-1200View

The DXD-1200 series flow pack packaging equipment is designed for packaging multiple small products in one package such as candy.

DXD-1200 series flow pack packaging equipment is a kind of up-film packing (HFFS) horizontal flow wrapper. With a vibrating bowl feeder and bowl feeder, this machine is suitable for the packing of small regularly-shaped products.

It adopts a rotating cutting device with six cutting heads. The cutting operation and packaging operation are carried out simultaneously, which improves production efficiency significantly. The maximum packaging speed can reach 1000bags/min. 1-5 candies can be packed each time.

-

-

-

- DXD-1600View

The DXD-1600 series flow pack packaging equipment is designed and manufactured for the packaging of small products such as candy, and more.

It is a kind of up-film packing HFFS wrapper, and it is also a flow-wrapping machine.

The automatic bowl feeder of DXD-1600 has a wide width of 1.2m, which makes the packaged products fall into the feeding device. Moreover, the DXD-1600 is equipped with six cutting heads so that it has a maximum packaging speed of 1400bags/min. Compared with the DXD-1200, the DXD-1600 has a lower empty bag rate, better quality and material utilization.

-